Batch reactors often have limitations due to the lack of precise reaction control, limited volumes and inaccurate temperature management.

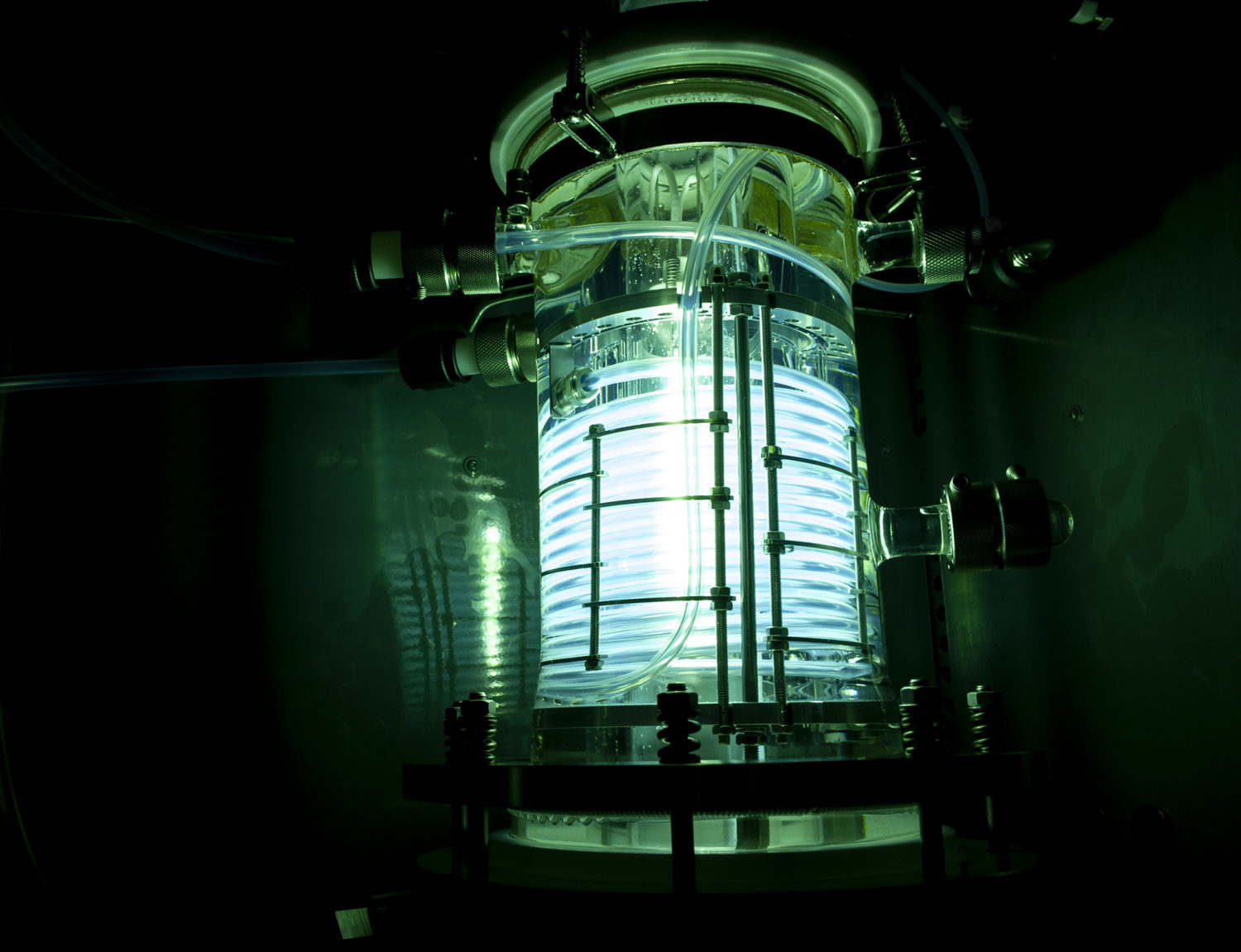

The photoFLOW reactor operates continuously, featuring a carrier design with FEP or glass tubes fixed around a carrier system and submerged in a temperature bath. A high-performance LED light source or a medium-pressure light source can be placed in the center of the tube carrier. This ensures that most photons are utilized in the process without large reflection losses. This setup allows for simple yet highly precise control of photochemical reactions in flow.

Continuous flow operation simplifies reaction progress tracking and optimization of existing processes, making it an ideal system for pharmaceutical applications. For example, the exact process control allows to limit the generation of unwanted by-products through over-irradiation.

The photoFLOW reactor offers several significant advantages. Firstly, it can be operated with low volumes in early development phases. Furthermore it provides controlled thermal conditions, ensuring that the temperature of the reaction is precisely maintained throughout the process. This level of control extends to the flow rate, allowing for consistent and reliable reaction progress.

Features

- Scalable tube photoreactor

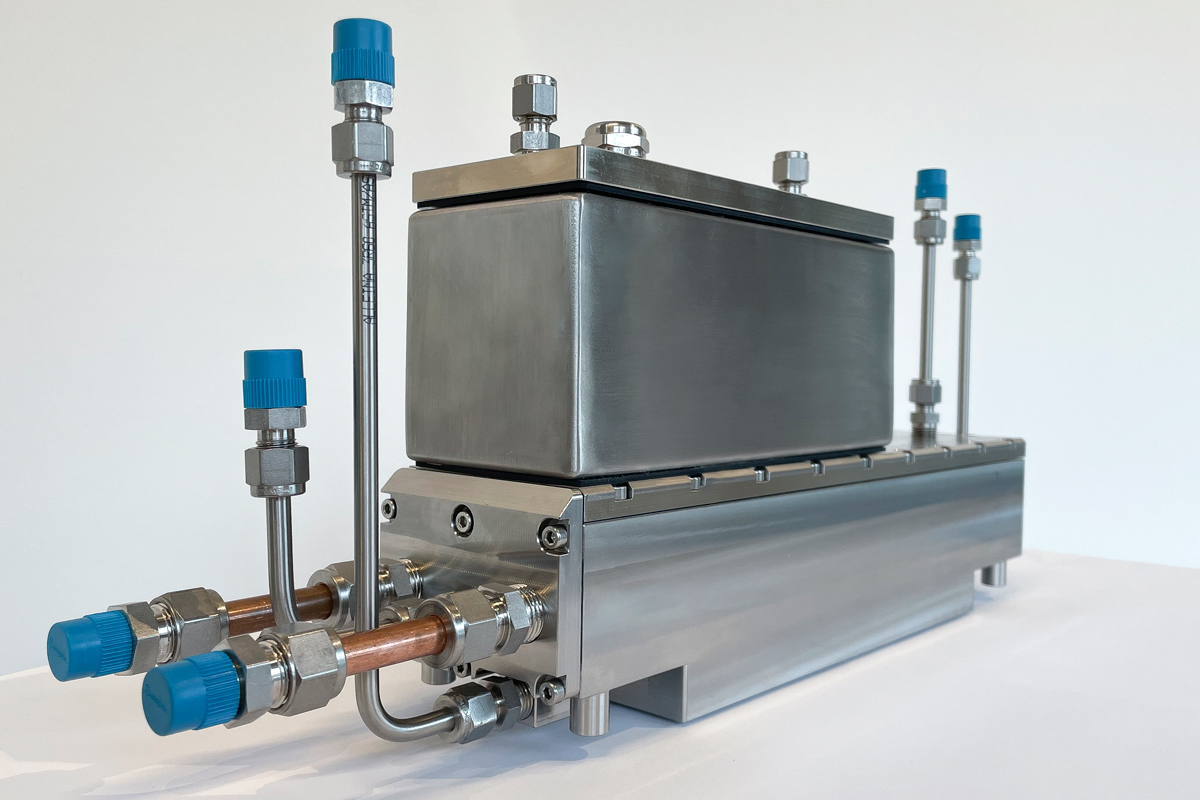

- Thermoliquid for temperature control

- Adjustable high power LED

- Easy scale-up for commercial production

Static mixing elements enforce a split and recombine flow pattern of the process stream, while a superimposed pulse allows to dramatically improve and regulate the turbulence and consequently mass- and heat-transfer. As this pulsating flow pattern technology decouples the hydrodynamics from the net flow rate, an intense mixing at all flow rates can be achieved.

The system also facilitates controlled turnover rates and the detailed analysis of reaction kinetics, making it easier to monitor and optimize reactions. With its design, the reactor also ensures a long residence time distribution, which is crucial for many photochemical processes.

Another key benefit is the high degree of mass transfer within the tubes, which enhances the efficiency of the reactions. The photoreactor can be operated in laminar, turbulent and plug-flow hydrodynamic conditions. The materials used in the reactor are chemically inert and consistent, ensuring durability and reliability in various chemical environments. Additionally, the photoFLOW reactor offers versatility with its range of tube diameters and the ability to adjust the length of the reaction zone according to the specific requirements of the process.

Easy scalable tube photoreactor

It is the first of its kind that can be easily scaled up to commercial levels, a feat previously unattainable with tube reactors. This innovative system allows all necessary parameters to be evaluated within the laboratory setup, enabling successful upscaling. By using this lab system, researchers can precisely determine and optimize the conditions needed for large-scale production, bridging the gap between small-scale experimentation and commercial application.

photoFLOW photoreactor in pilot size

photoFLow photoreactor in commercial size

Typical applications

Active pharmaceutical intermediates (API), e.g. synthesis of Artemisinin (antimalarial drug), singlet oxygen reaction

API and intermediate synthesis (e.g. Iribotecan by Cis-Trans Isomerization and Artemisinin by Singlet Oxygen Reaction)

API carriers and particle modifications

API synthesis

Production of Vitamins

Brominated intermediates for synthesis

Chlorinated intermediates for synthesis

Fluorinations, Sulfoxidations, Nitrosylations

Fragerances

Plant treatment intermediate

Polymer functionalization

Preparative photochemistry in general implying strongly absorbing substrates and/or radical imtermediates

Safety agents

Flatbed photoreactors

Further products on request

Download

Photoreactors PDF

Please enter your name and Email address to generate a download link directly.

Any questions?

Please ask us