The efficient irradiation of liquids with low transmittance represented a hitherto unresolved challenge for the development of some photochemical processes. If there is a lack of penetrative depth, photons are absorbed within shortest distance at the boundary surface. The optical path of conventional reactors being far too large, the majority of the volume to be irradiated passes the reactor without exposition to the incident radiation, and, consequently, the photochemical process remains inefficent. Furthermore, and in particular in the case of photochemical reactions implying radical intermediates, mostly macromolecular secondary products may form and may be deposited at the boundary surface of the immersion lamp system (“filming”). These deposits additionally absorb the photons emitted by the lamp and, in extreme cases, may lead to overheating of a conventional photoreactor.

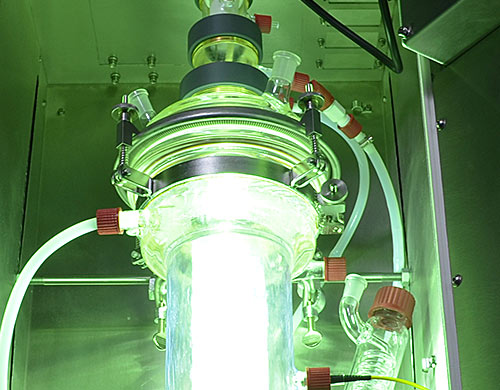

The Peschl Falling-Film photoreactor has a special design that permits efficient irradiation of liquids with low transmission in the form of an evenly falling-film with high turbulence (tumbling) and low layer thickness. Deposits on the jacket tube are prevented, as the liquid film has no physical contact with the immersion lamp system. A minimum flow rate is required to produce a constant and equilibrated falling-film within which the turbulence is characterized by Reynolds number of Re > 400.

The unique design of the overflow edge and liquid distribution prevents that the film is tearing off and simplifies considerably the levelling of the equipment. In direct comparison to an annular thin layer photoreactor, the advantage of the falling film photoreactor for liquids with low transmittance is obvious. The residence time in the first is severly limited by the high flow required to achieve turbulence, while in the falling film photoreactor, the residence time depends on the length of the falling film, and turbulence depends on the thickness of the falling film and, hence, within given limits on the flow of the solution to be irradiated.

The Peschl Falling-Film photoreactor has been designed in such a way, that the incident radiant power density can be adjusted and optimized for a given photochemical reaction by varying the irradiated film surface (cm2). With this design, highly efficient photo-reactors are offered – tailor-made for each process – and additionally equipped with a temperature control cladding, through which a reaction can be cooled or heated in the range from -80ºC to +120ºC.

With the falling film photoreactor from Peschl Ultraviolet GmbH, photochemical reactions of very strongly absorbing substrates can now be realized successfully.

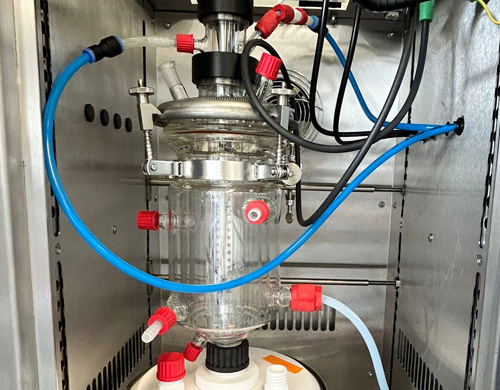

Pilot photoreactor systems are available to guarantee a safe up-scaling process in complex synthesis steps, with the aim to quantify the space-time yield and productivity of the industrial-sized photoreactor. With this data, more precise CAPEX and OPEX analysis can be performed and hydrodynamic effects can be analysed and understood.

Industrial-size photoreactors are commercially available and tailor-made for each individual process. However, based on the high level of standardized components, such as immersion lamps with Ex-approvals, this task is routine and can be performed fast and reliable with the power density required for highly efficient production.

Typical Processes

- Vitamin D production (prone of filming if high radiant power densities are applied)

- Preparative photochemistry in general implying strongly absorbing substrates and/or radical imtermediates

- Recovery of precious metals

- Photooxidations implying radical intermediates (e.g. AOP)

- Bleaching

- Aqueous dispersion of polymers that can be solidified into rubber (Latex)

- Monomer modification

- API synthesis

Technical Features of Falling-Film Photoreactors

- Designed to irradiate homogeneous and heterogeneous (liquid/liquid) reaction systems containing strongly absorbing substrates

- Separation from lamp and product to prevent filming on the boundary surface

- Appreciable turbulence and high molecule exchange rate at low flux

- Prevention of over-irradiation

- Fixed residence time in the irradiated reactor zone

- Optimized irradiance for a given photochemical reaction

- Film equally distributed allover the irradiated surface by special reactor design

- High cooling efficiency through the reactor wall

- Ex-proof design of all components

- Electric power consumption up to 60 kW per lamp

- Gas-discharge, Excimer and LED lamps

- Process temperatures from -80°C up to +120°C

- Robust and reliable reactor designs for safe production

- Special construction materials (reactor tank: titanium, ceramics or special glass-lining for aggressive process conditions

Services we offer

- Engineering and supply of industrial-sized photochemical reactors

- Scale-up of your process from lab-size to industrial-size

- Scale-down of your process from industrial-size to mini-plant-size

- Photochemical process consultancy

- HAZOP studies for safe operation

- Commissioning support, on-site service

Any questions?

Please ask us